Kubota came to this year’s CES with a sprawling display filled with electric equipment, hydrogen gensets, and an onslaught of commercial robots ready to mow, farm, dig, and build. If you weren’t impressed by Kubota’s display this year, you weren’t paying attention.

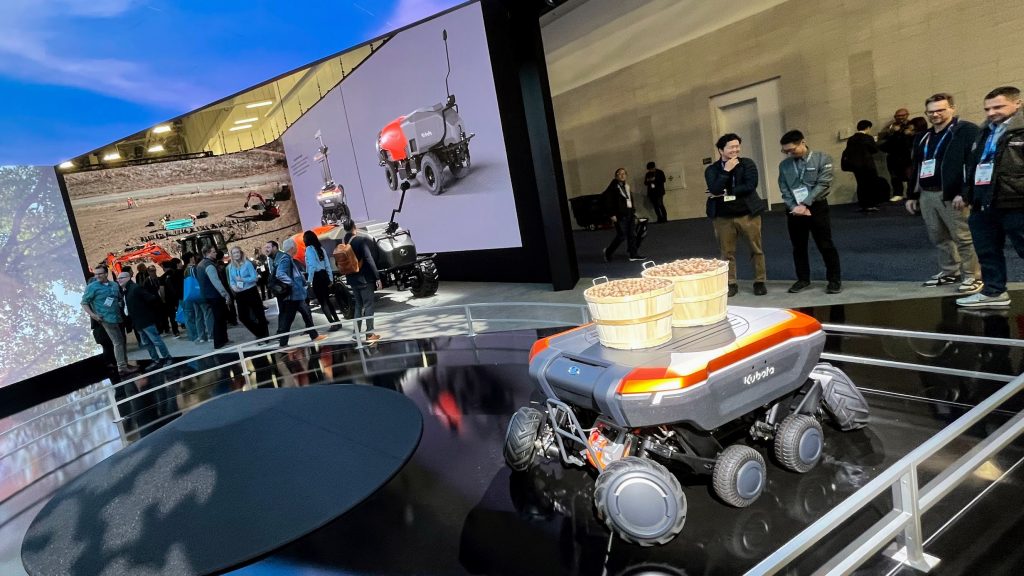

Kubota gave us a sneak peek of its KATR farm robot – itself a smaller, updated version of last year’s New Agri Concept – before the doors officially opened last week. Kubota’s robotic farm buddies promise to be able to quietly and autonomously haul stuff from one end of the farm to another, or pull carts and specialized implements along predetermined paths.

KATR uses self-leveling technology and active suspension to ensure its cargo deck stays level when working on the sort of uneven terrain found on farms or construction sites.

That doesn’t mean the New Agri Concept is dead, though. Agri Concept 2.0 debuted as an electric tractor concept offering AI-powered automation and a fully electric powertrain. The new version features a Lite Brite-style “grille” that it uses to communicate its current mode, direction, and other important information with the people it shares a job site with.

On the more practical side, Kubota showed off its KX38-4e Electric compact excavator. First shown in overseas markets in 2022, the KX38-4e Electric features a 49.2 kWh lithium-ion battery that’s good for up to five hours of continuous operation. More than enough to complete a typical day of work on a construction site when you factor out idle time.

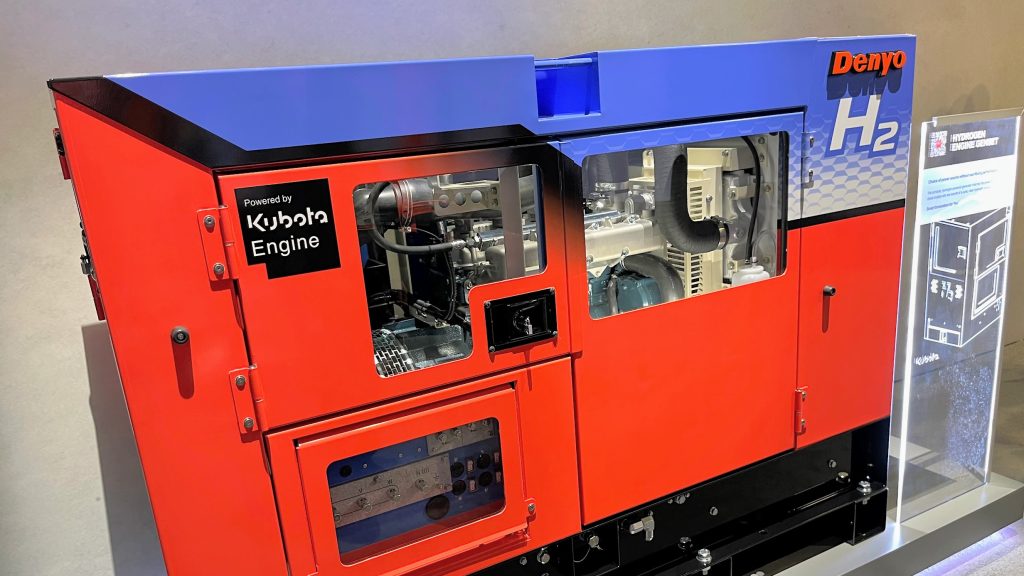

An onboard DC fast charger means it can be quickly recharged between shifts, too. But when there’s no grid power on the site, charging can be a challenge. That’s why Kubota has hydrogen genset for zero-emission on-site power generation.

Looked at individually, each of the new electric Kubota products on display might be impressive. The real magic, though, is in the way the Kubota machines work together as a holistic job site or farm solution.

“At Kubota, we believe that truly listening to our customers drives innovation in every aspect of what we call the ‘Work Loop’,” explains Brett McMickell, Chief Technology Officer of Kubota North America. “The Work Loop — an essential cycle of assessing, analyzing, and acting — has always been fundamental to effective task management. With the integration of advanced sensors, AI-driven analysis, networking protocols, automation, and robotics, we are enhancing this cycle to be more seamless and efficient than ever before.”

That was obvious in some of the more thoughtful implements and attachments on display, including a Smart Plant Imager that uses advanced robotics and “hyper-spectral imaging” cameras to capture real-time data and insights on a plant-by-plant level – as well as a Smart Autonomous Sprayer and Robotic Pruner that that classifies buds and canes based on position and fruiting potential, it optimizes production precision and accuracy.

The more you look, the more impressive Kubota’s farming solution gets. “We will continue to learn from many of our customers across segments to iterate the next product and technology solution that will help them manage tomorrow’s challenges and grow their businesses,” McMickell added. “This is how Kubota works to make a better quality of life for individuals and society.”

There was more, of course. Autonomous versions of the company’s electric zero-turn mower with GPS-powered route memory, fun accessory baskets for the robots, even a weird, jet engine looking thing that I forgot to ask about (below). I was genuinely impressed, in other words, and can’t wait to see what Kubota comes up with next year.

Kubota CES2025 | more photos

Original content from Electrek.